Well the solar array and batteries are holding up quite well and performing well above my expectations. But that will be changing soon as we head into shorter and rainy days. We already had our first rainfall and it was telling. I will definitely need to come up with a new method of power generation, and I have!

So the story goes like this, we have been making some additions to our cabin as the wife FINALLY is starting to accept we are not going to get the main house done anytime soon. So we are making our cabin a bit more livable for a family of 4 +1. We have added a room for her son and another room that will attach to the shower / bathroom area. In the new adjoining room we have installed a small wood stove to heat the cabin with, thereby eliminating the propane heater from the power equation.

Well, while I was installing the wood stove I started thinking "There has to be some way to generate power from the heat this thing puts off." And lo and behold, someone at GlockTalk (a forum I enjoy frequenting!) posted this link:

http://shop.biolitestove.com/BioLite-CampStove_p_15.html

And so that link sent me on a crazy search to find out how the hell they are doing that and, the technology is space age yet so simple to build!

http://en.wikipedia.org/wiki/Thermoelectric_generator

Anyhow I kept digging around, wanting to learn as much as I can before I pursue this and I found this nugget!

http://www.youtube.com/watch?v=zzEK5eODr6I&feature=related

So that got me to thinking even more. I do that a lot... thinking. Gets me into a lot of trouble sometimes. Anyhow after watching how the fellow in the above YouTube video was able to create a generator using nothing more than some dissimilar metal, a candle and his hand I figure I can do the same thing but on a larger scale. The idea I have is to take some copper rods and stainless steel rods (those are the metals he used in the video so stick with what I know to work) one of my 55 gallon drums and I can poke the rods though the drum, make the connection internally and have the other end out in the cold weather.

This would give me a greater potential for voltage using the larger pieces of metal while also giving me a natural method for creating the thermal difference needed. I have a friend that I will work with to get this up and going and I believe I should be able to get one up and running this weekend if not sooner. While the idea I have does not use the wood stove we have installed (although if it works well enough I might be able to adapt to the wood stove in the future) it does use what I have on hand to generate literally free power.

I say literally because there is the cost of some of the components plus my time invested into the process. But if I can get this designed right and get a reliable 28 - 34VDC from this set up, then I can connect wires and run this to my charge controller on the wind side. My Trace Xantrex PWM charge controller has connections for solar and wind. The solar is already connected and the wind side could be used for my thermoelectric generator.

The key here is getting the voltage range I need. Because on nasty days I can easily start a fire and let it burn untended for up to 2 hours before I need to add fuel (I know this because of experience with another burn barrel we have set up for heating water for the kids red-neck pool).

So the resources I have on hand right now are two 55 gallon drums, plenty of heavy duty aluminum electrical wire (gift from a friend) the charge controller and at least one stainless steel bar. So I would have to get a similar sized copper bar and connect the two together. I can also use bricks to create an additional thermal barrier between the barrel and the cold side.

I will need to get a thermometer gun so I can measure temperature of the hot and cold sides and compare those to voltages and amperage generated. Doing this will allow me to chart out the performance of the components and gauge what I need to do to hit my voltage range needed. Also I can then start trending for run times versus performance. If I get this dialed in really well then I can potentially create one of these generators to run our well pump thereby eliminating the gasoline powered generator for all but extreme emergencies. My research has shown that this is theoretically possible, but I haven't really found much on the large scale other than industrial.

Well, that's all for now! I will keep you posted and of course as things move along I will take photos and post them up with the performance numbers I get.

Peace Love and Five Finger Death Punch!

A painful step by step description of how I am setting up my own off-grid power system.

Is anybody looking?

Thursday, October 18, 2012

Wednesday, October 3, 2012

System Performance Load Testing

Hello! So the last week I have been conducting a system performance load test. The idea is to see how well my batteries hold up while being loaded and charged simultaneously. So I have isolated bank 1 of batteries and currently have bank 2 of batteries on load and charge. Now the days are getting shorter and the last couple of days have been hot as hell (over 100F.!!!). So that tends to decrease efficiency due to increases resistance from the excessive heat.

Well, the system is performing perfectly! I have 4 - 380AH 6V deep cycle batteries in a 24V configuration with 1.28+kW of monocrystaline panels for input. The load as noted in earlier posts are my deep freezer, refrigerator and TV/DVD combination with some smaller charging loads (cell phone for wife, laptop and battery pack for drills).

Now if you remember in previous posts I set the system up to have one bank on charge and one on load. Well the wife challenged me and my systems capability to carry the load. So I took bank 1 off charge after it was topped and equalized (love these new charge controllers!) and placed bank 2 on charge and load. And we are not only carrying the load but when I get home the batteries are showing between 96 - 99% charge, meaning they were topped and floated by the charge controllers.

The problem we will be running into in the near future will be cloudy days and shorter charge times. Fortunately the panels can recover an unloaded battery bank with moderate cloud cover. But we are heading into our winter and while it's short, it's almost like being in Seattle. So I have been "selling" the wife on a wind turbine for winter power production. Where we live we get a great deal of wind during the winter and what I noticed is that if it's cloudy... it's windy. We really do have an off-gridders piece of prime real estate!

Well that's all for now... have to get back to work but just wanted to post an update. And yes, I do have some performance data that I will post as well. It's getting more accurate as I establish my routines and now that I have a thermometer in place I can start tracking weather and temperatures as well. This is all information I will use for the main 48V system I will have to design and build sometime in the future when the house is actually ready. And the data I collect might be of some use to any of you that actually are reading this blog!

Peace, Love and Five Finger Death Punch!

Well, the system is performing perfectly! I have 4 - 380AH 6V deep cycle batteries in a 24V configuration with 1.28+kW of monocrystaline panels for input. The load as noted in earlier posts are my deep freezer, refrigerator and TV/DVD combination with some smaller charging loads (cell phone for wife, laptop and battery pack for drills).

Now if you remember in previous posts I set the system up to have one bank on charge and one on load. Well the wife challenged me and my systems capability to carry the load. So I took bank 1 off charge after it was topped and equalized (love these new charge controllers!) and placed bank 2 on charge and load. And we are not only carrying the load but when I get home the batteries are showing between 96 - 99% charge, meaning they were topped and floated by the charge controllers.

The problem we will be running into in the near future will be cloudy days and shorter charge times. Fortunately the panels can recover an unloaded battery bank with moderate cloud cover. But we are heading into our winter and while it's short, it's almost like being in Seattle. So I have been "selling" the wife on a wind turbine for winter power production. Where we live we get a great deal of wind during the winter and what I noticed is that if it's cloudy... it's windy. We really do have an off-gridders piece of prime real estate!

Well that's all for now... have to get back to work but just wanted to post an update. And yes, I do have some performance data that I will post as well. It's getting more accurate as I establish my routines and now that I have a thermometer in place I can start tracking weather and temperatures as well. This is all information I will use for the main 48V system I will have to design and build sometime in the future when the house is actually ready. And the data I collect might be of some use to any of you that actually are reading this blog!

Peace, Love and Five Finger Death Punch!

Thursday, September 13, 2012

We are operational and it's good!

Okay, so here we are now almost a month since the meltdown. I have the system up and running and we will be adding two new panels this Friday. So how and what did I do? Well once I calmed down from the excitement of cooking $1200.00 worth of solar panels I looked into how the error occurred then set in motion a plan of recover and written instruction manual for me to follow. As noted in my last post I changed my battery configuration so I could maximize the potential of my panels to recover my batteries.

Now what the last couple of weeks have shown me is that my math isn't supporting reality. According to the math I should be able to operate for two days on batteries with no charge coming and at that point the batteries should be at about 60%. Well reality is I can operate one day before I hit the 60% mark. The good news is that it's been consistent everyday so I feel confident in my system design changes.

Now the system as it stands consists of the following components:

- 2 Talesun 250W 24V monocrystaline panels

- 1 Renesola 260W 24V monocrystaline panel

- 3 Helios 7T2 300W 24V monocrystaline panels (severely damaged)

- 1 Trace Xantrex C40 PWM charge controller

- 1 Blue Sky Solar Boost 3024iL MPPT charge controller

- 1 Tripp-Lite 24V 2400W PowerVerter inverter

- 8 US L16XC 6V 380Ah deep cycle batteries

- 1 Custom built combiner box

- 3 15A DC rated circuit breakers

- 3 15A DC rated quick burn fuses

- 2 8 connection DIN rails

- 3: 4 position DC rated switches (Off, 1, 2, Both)

- 1 two position DC rated switch

As I stated in the beginning of this post, we are getting two more of the 260W Renesola panels, so that will bring me up to a total of 1.28kW potential power generation plus whatever the three Helios panels are producing. I haven't really taken the time to figure out what they are actually generating in terms of power yet. Eventually we will be getting a wind turbine as well, but for the interim we will have to rely strictly on solar.

Okay so now for some gratuitous images! Yes... I am sure things could be cleaner, nicer and so forth. If you have the $$$ and spare time you are more than welcome to come on over and lend a hand! But this is how it is in the real world where people don't have lot of disposable income. It works, it isn't pretty but it works.

So that's it for this post, I will be updating periodically as changes are made and with some actual tracking data of the systems performance. I am just now starting to obtain data and it's not easy to collect it all. But I am getting it. Peace, love and Five Finger Death Punch... good luck in your solar adventures, I do hope you have learned from my mistakes and successes.

Now what the last couple of weeks have shown me is that my math isn't supporting reality. According to the math I should be able to operate for two days on batteries with no charge coming and at that point the batteries should be at about 60%. Well reality is I can operate one day before I hit the 60% mark. The good news is that it's been consistent everyday so I feel confident in my system design changes.

Now the system as it stands consists of the following components:

- 2 Talesun 250W 24V monocrystaline panels

- 1 Renesola 260W 24V monocrystaline panel

- 3 Helios 7T2 300W 24V monocrystaline panels (severely damaged)

- 1 Trace Xantrex C40 PWM charge controller

- 1 Blue Sky Solar Boost 3024iL MPPT charge controller

- 1 Tripp-Lite 24V 2400W PowerVerter inverter

- 8 US L16XC 6V 380Ah deep cycle batteries

- 1 Custom built combiner box

- 3 15A DC rated circuit breakers

- 3 15A DC rated quick burn fuses

- 2 8 connection DIN rails

- 3: 4 position DC rated switches (Off, 1, 2, Both)

- 1 two position DC rated switch

As I stated in the beginning of this post, we are getting two more of the 260W Renesola panels, so that will bring me up to a total of 1.28kW potential power generation plus whatever the three Helios panels are producing. I haven't really taken the time to figure out what they are actually generating in terms of power yet. Eventually we will be getting a wind turbine as well, but for the interim we will have to rely strictly on solar.

Okay so now for some gratuitous images! Yes... I am sure things could be cleaner, nicer and so forth. If you have the $$$ and spare time you are more than welcome to come on over and lend a hand! But this is how it is in the real world where people don't have lot of disposable income. It works, it isn't pretty but it works.

| Here is my combiner box where you can see both the breakers and fuses. |

| A close up of each breaker I have them labeled for each panel in case I need to remove a specific panel I can just isolate the one panel and leave the system operational. |

| And a full view of the inside of the box. |

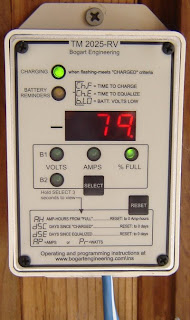

| Here are the two charge controllers I have in use at the moment. |

| The two panels you can see pretty clearly are the Talesun 250W, this photo was taken just prior to the Renesola panel being installed. The Helios panels are just below the Talesun panels. |

Friday, August 24, 2012

Oh the pain... the PAIN!

Okay, so where to start, well how about with stupid hurts. This time my pocket book. So the last week has been a nightmare for me as I have managed to seriously damage my 3 – 300W solar panels and my ego too. So let us start from the beginning and move through a time of much pain.

It seems to have all started with the inverter. The last piece of the puzzle I needed to get my system up and running. Finding a reasonably priced 24VDC inverter that could at least stand up to the demand I am going to put it through was difficult. Then factor in $$$ is an issue. Yeah, when isn't it? Anyhow I finally get an inverter as noted in an earlier post, but it's pretty much DOA. Anyhow I finally get that resolved and now have a Tripp-Lite 2400W 24VDC inverter online and operational.

So I get the batteries online and I have the generator running to top the batteries off and to run my fridge so I can get the temp down and reduce the load on my batteries during the start up of my off-grid array. Makes sense since I have a lot of heat to remove (the refrigerator has been off line for almost a year) from the fridge and that was going to take a lot of power and time.

In total it took 8 hours on the generator to get the fridge temps stable for the most part. But the compressor was still cycling a lot and as noted in the owners manual that was normal for the first 24 hours after start up and or a major change in temperature control. Now here is where things get cool... no pun intended... or maybe there is? I knew from my research that running a fridge off-grid was going to require extra insulation in order to reduce energy demands once the temperature was stable. So part of my off-grid design and plan was to wrap both my refrigerator and deep freeze with an extra layer of insulation. By doing this I could slow the transfer of heat and thereby increase the efficiency of both components.

I calculated about a 35-40% increase in efficiency. I need to go back to school as my math SUCKS! I am getting about a 70% increase. Okay let's quantify this. So under normal operations without the extra insulation my refrigerator consumes about 1.2 to 1.4kWh of power a day. This is verified through a Kill-A-Watt over a 2 week period (back when I was designing the system and learning the power demands of my existing devices). Using the same Kill-A-Watt after the fridge had reached thermal stability total power use over a 24 hour period for the last 5 days has been 360Wh. Yes you read that correctly By adding a double radiant barrier 2in thick insulation to the outside of my fridge I have seen a reduction of 840Wh of power consumption. Good thing too... if you keep reading you will understand why.

Okay, now let us get back to the rest of the system. SO we ran the fridge on batteries for 5 days before the inverter shut off on a low voltage alarm. Yeah, we ran the batteries down to 10%!!! WHAT THE $^&#!!!! How the hell?!?!?!? Oh, it gets real good from here. So let's go to the charge controller I got from Missouri Wind and Sun. It came with two sets of instructions that conflicted with each other and that had not only myself confused, but an electrical engineer (friend I had checking my system out and answering questions) but another fellow that is far more intelligent than I am. After 2 days we finally agreed on a method to connect the charge controller to the panels. So we did it and... nothing was working?

Well no worries, we are charging the batteries off the generator. See we sell water from our property to a fella that trucks it to people in the area that need water but are not connected to the city and or whose wells dried up back during the Loma Prieta earthquake in 1989. So when we pump right now we run a generator to do this, so we will charge batteries and do laundry and so forth. Well this is where I got hammered, the battery charger I bought said it was designed for 12 and 24V systems. So I wired it to charge my 24V battery array. And I didn't bother to verify by taking voltage readings and just assumed because the lights were on that the charger was doing it's job. Well when the batteries died, that's when I started to investigate and found that NO the charger WAS NOT DESIGNED for a 24V system... even though it says so on the box! So while I thought it was charging... it wasn't.

Well the day before everything came crashing down I called Missouri Wind and Sun and explained my dilemma (the panels were still not charging) and they told me how to wire the panels to the charge controller (so word of advise... stick with Trace Xantrex, Outback and Blue Mountain... more on that later.) So after getting off the phone I realize that I have my panels wired to the wrong side of the solenoid on their charge controller. So essentially I had dead headed my panels. Okay no worries I can fix this when I get home. Yeah... I fixed it alright!

Now a little lesson and you better pay real close attention here... it's so important that I will now increase the font size AND put the text in bold red.

Pay close attention here, on MC4 connectors there is a + and a - side. The positive side is the male side and the negative side is the female side. This is true even on the panels themselves!! DO NOT CONNECT YOUR MC4 CABLES TO YOUR COMBINER BOX UNTIL YOU HAVE VERIFIED POLARITY!!! When you connect the MC4 cable positive leg to your panels MC4 negative leg that MC4 cable is now negative!! And the same is true of the MC4 cable negative leg that is connected to your panels positive MC4 leg that negative cable becomes positive.

I made the mistake of connecting my MC4 cables to the combiner box using the polarity markings on the cables as my guide. This basically set me up for failure. What pushed this failure into motion was the fact the Helios panel MC4 cables were NOT marked. Here is where a polarity test should have been done, but I made an assumption and was wrong. So basically I wired my panels in reverse and didn't realize it. Now when I got home to wire the combiner box out put cables to the charge controller I isolated the panels with the switch I put in place for things like this. Keep in mind each panel is circuit protected with a 15A breaker (now that is changing as I will double protect with both a fuse and breaker)

So I made the connection corrections then placed the panels online... the time it took my to flip the switch and walk out to where my panels are mounted was about 3 seconds. In that time I burned my panels. See the images of shame below.

I isolated the panels as quickly as I could but the damage was already done. In less than 5 seconds I damaged severely $1200.00 worth of solar panels and for the first time in many, many years... I broke down crying in frustration. This entire project has been one issue after another. Even with all my careful planning and research I ran into issue after issue after issue. This was the final straw that pushed me over the edge. I was pretty close to just giving up completely as I was tired of the constant struggle to have what is so easily obtained in this country... power.

But I am stubborn and refused to give up, even though I had burned my panels, purchased the wrong battery charger, purchased a non-standard charge controller and drained my batteries down to 10%... I couldn't just quit. So it's been over a week now and we have power somewhat. Even though the panels are seriously damaged (all three together produce maybe 300W of power) they are maintaining my batteries at 85%. Currently the only load I have is the fridge and the inverter. I have since taken half my batteries to my brother in-laws and put them on charge for the last 5 days. Today that bank comes home and the bank in service will be delivered for their 5 days on charge.

The panels replace all the power we consume with a slight increase over demand. But as we move into shorter days that will cease to be a truism. I have right now 2 - 250W Talesun 24V panels on order for pick-up in San Jose. I should be getting them Monday or Tuesday. I also got a good deal on a Blue Mountain MPPT charge controller AND I just found a place just outside of San Francisco where they have new solar panels for as low as $0.75/W and since I can DRIVE THERE, it's well worth it. The panels are brand new and basically are extras that are not needed. See, to get a decent price on panels you have to order them by the pallet. If you order individually you pay more per watt and even more for shipping (how the hell does that work?!?). So installers will order pallets of panels, install what they need for the job they are on then the left overs are either used in another project or this guy gets them and turns around and sells them

http://king-solarman.com/ This is the local place where I will be getting all my future panels. Another place you the reader can look is here: https://pvdepot.com/ this is who I ordered my two new Talesuns from.

So the two new panels will be coupled with the new Blue Mountain MPPT charge controller and the damaged Helios panels will be maintained on the Trace Xantrex PWM charge controller I got from a friend as a gift. Helios has agreed to work a deal with me so I can replace the panels at a special rate, what that rate is I won't find out until either Monday or Tuesday. I did open a dialog with Helios the day everything happened. In the beginning I thought it was the charge controller but as time passed and I continued my investigation I found where I had made my error. But I also noted that Helios had failed to mark their MC4 connections with polarity. Granted someone in the business would already know many of the things I now do... but I am an amateur that lives off grid trying to save some hard earned cash and get power up.

At the end of next month I will have my system up and all my appliances running on it. The 12V system I started with will be partially dismantled and used for lighting only in the cabin. The remainder will be used to generate power in another location for lights and laptop / printer operations for my wifes business. It's funny how easy life is in the United States and you don't realize it until you move away from it and live outside the box. It's hard and it's frustrating and it's initially expensive. But in the end it's worth the freedom. I will leave this with an image of the next step in my systems implementation, a step that I will start to put in place next weekend (I have the property all to myself for 4 days!!!). Oh and a side note, once I have the new panels working I will remove the 3 damaged panels (after the replacements arrive) and use the worst of the three panels as a source of cells and see if I can repair the other two panels. I have been reading up and watching YouTube videos on how to do this... I figure might as well since the warranty is void anyhow. What could I possibly do wrong?

Well, that's all for now... well... not really... below is the e-mail I sent to Helios the day I realized my error.

Dear Mr. Brucker,

It is with extreme humility that I write to inform you that the damage to the panels is due to reverse wiring, which was done by myself. The only thing that would be "wrong" on the side of Helios, is that the MC4 connectors on the panels were not clearly marked positive / negative as the MC4 cables I used to connect the panels to the combiner box were. Essentially I used the markings on the MC4 cables that I bought separate from the panels as my guide to connecting the terminal leads to the combiner box, reversing the polarity in doing so. I also failed to take voltage readings prior to energizing the string to the charge controller, and had I done so I would have noted the reversed polarity and been able to correct it then, and only I can be held culpable for this.

I humbly apologize for any inconvenience I may have caused with this "issue". Essentially I made a rookie mistake one that I didn't make with my 12V system as the connectors on the panels were clearly marked and that let me know how to connect the wires to the combiner box. How this happened is that when I was connecting the 12V panel to my other system, I saw the + symbol on the solar panel connector and when I plugged it into the MC4 cable, it was the - cable that went into the + cable. Seeing this I realized then that what it marked - is actually + and + is actually -. I came to this realization this morning after sleeping on the issue at hand when I woke up, went out to the array and validated it with a multi-meter.

My wife has asked that I inquire about the possibility of replacing these panels at cost, and all I can do is ask. I realize and admit that I am the one that made the mistake (one I will never make again), and that the only culpability I can find on the part of Helios is the lack of polarity identification on the MC4 connectors / cables on the panels which influenced the error. In closing thank you for your time and effort on this matter.

Sincerely,

McDian

It seems to have all started with the inverter. The last piece of the puzzle I needed to get my system up and running. Finding a reasonably priced 24VDC inverter that could at least stand up to the demand I am going to put it through was difficult. Then factor in $$$ is an issue. Yeah, when isn't it? Anyhow I finally get an inverter as noted in an earlier post, but it's pretty much DOA. Anyhow I finally get that resolved and now have a Tripp-Lite 2400W 24VDC inverter online and operational.

So I get the batteries online and I have the generator running to top the batteries off and to run my fridge so I can get the temp down and reduce the load on my batteries during the start up of my off-grid array. Makes sense since I have a lot of heat to remove (the refrigerator has been off line for almost a year) from the fridge and that was going to take a lot of power and time.

In total it took 8 hours on the generator to get the fridge temps stable for the most part. But the compressor was still cycling a lot and as noted in the owners manual that was normal for the first 24 hours after start up and or a major change in temperature control. Now here is where things get cool... no pun intended... or maybe there is? I knew from my research that running a fridge off-grid was going to require extra insulation in order to reduce energy demands once the temperature was stable. So part of my off-grid design and plan was to wrap both my refrigerator and deep freeze with an extra layer of insulation. By doing this I could slow the transfer of heat and thereby increase the efficiency of both components.

I calculated about a 35-40% increase in efficiency. I need to go back to school as my math SUCKS! I am getting about a 70% increase. Okay let's quantify this. So under normal operations without the extra insulation my refrigerator consumes about 1.2 to 1.4kWh of power a day. This is verified through a Kill-A-Watt over a 2 week period (back when I was designing the system and learning the power demands of my existing devices). Using the same Kill-A-Watt after the fridge had reached thermal stability total power use over a 24 hour period for the last 5 days has been 360Wh. Yes you read that correctly By adding a double radiant barrier 2in thick insulation to the outside of my fridge I have seen a reduction of 840Wh of power consumption. Good thing too... if you keep reading you will understand why.

Okay, now let us get back to the rest of the system. SO we ran the fridge on batteries for 5 days before the inverter shut off on a low voltage alarm. Yeah, we ran the batteries down to 10%!!! WHAT THE $^&#!!!! How the hell?!?!?!? Oh, it gets real good from here. So let's go to the charge controller I got from Missouri Wind and Sun. It came with two sets of instructions that conflicted with each other and that had not only myself confused, but an electrical engineer (friend I had checking my system out and answering questions) but another fellow that is far more intelligent than I am. After 2 days we finally agreed on a method to connect the charge controller to the panels. So we did it and... nothing was working?

Well no worries, we are charging the batteries off the generator. See we sell water from our property to a fella that trucks it to people in the area that need water but are not connected to the city and or whose wells dried up back during the Loma Prieta earthquake in 1989. So when we pump right now we run a generator to do this, so we will charge batteries and do laundry and so forth. Well this is where I got hammered, the battery charger I bought said it was designed for 12 and 24V systems. So I wired it to charge my 24V battery array. And I didn't bother to verify by taking voltage readings and just assumed because the lights were on that the charger was doing it's job. Well when the batteries died, that's when I started to investigate and found that NO the charger WAS NOT DESIGNED for a 24V system... even though it says so on the box! So while I thought it was charging... it wasn't.

Well the day before everything came crashing down I called Missouri Wind and Sun and explained my dilemma (the panels were still not charging) and they told me how to wire the panels to the charge controller (so word of advise... stick with Trace Xantrex, Outback and Blue Mountain... more on that later.) So after getting off the phone I realize that I have my panels wired to the wrong side of the solenoid on their charge controller. So essentially I had dead headed my panels. Okay no worries I can fix this when I get home. Yeah... I fixed it alright!

Now a little lesson and you better pay real close attention here... it's so important that I will now increase the font size AND put the text in bold red.

Pay close attention here, on MC4 connectors there is a + and a - side. The positive side is the male side and the negative side is the female side. This is true even on the panels themselves!! DO NOT CONNECT YOUR MC4 CABLES TO YOUR COMBINER BOX UNTIL YOU HAVE VERIFIED POLARITY!!! When you connect the MC4 cable positive leg to your panels MC4 negative leg that MC4 cable is now negative!! And the same is true of the MC4 cable negative leg that is connected to your panels positive MC4 leg that negative cable becomes positive.

I made the mistake of connecting my MC4 cables to the combiner box using the polarity markings on the cables as my guide. This basically set me up for failure. What pushed this failure into motion was the fact the Helios panel MC4 cables were NOT marked. Here is where a polarity test should have been done, but I made an assumption and was wrong. So basically I wired my panels in reverse and didn't realize it. Now when I got home to wire the combiner box out put cables to the charge controller I isolated the panels with the switch I put in place for things like this. Keep in mind each panel is circuit protected with a 15A breaker (now that is changing as I will double protect with both a fuse and breaker)

So I made the connection corrections then placed the panels online... the time it took my to flip the switch and walk out to where my panels are mounted was about 3 seconds. In that time I burned my panels. See the images of shame below.

| This is the middle panel in the array of three. |

| A close up of the middle panel. |

| This is the left panel and the furthest from the charge controller |

| Top view of the damage. |

But I am stubborn and refused to give up, even though I had burned my panels, purchased the wrong battery charger, purchased a non-standard charge controller and drained my batteries down to 10%... I couldn't just quit. So it's been over a week now and we have power somewhat. Even though the panels are seriously damaged (all three together produce maybe 300W of power) they are maintaining my batteries at 85%. Currently the only load I have is the fridge and the inverter. I have since taken half my batteries to my brother in-laws and put them on charge for the last 5 days. Today that bank comes home and the bank in service will be delivered for their 5 days on charge.

The panels replace all the power we consume with a slight increase over demand. But as we move into shorter days that will cease to be a truism. I have right now 2 - 250W Talesun 24V panels on order for pick-up in San Jose. I should be getting them Monday or Tuesday. I also got a good deal on a Blue Mountain MPPT charge controller AND I just found a place just outside of San Francisco where they have new solar panels for as low as $0.75/W and since I can DRIVE THERE, it's well worth it. The panels are brand new and basically are extras that are not needed. See, to get a decent price on panels you have to order them by the pallet. If you order individually you pay more per watt and even more for shipping (how the hell does that work?!?). So installers will order pallets of panels, install what they need for the job they are on then the left overs are either used in another project or this guy gets them and turns around and sells them

http://king-solarman.com/ This is the local place where I will be getting all my future panels. Another place you the reader can look is here: https://pvdepot.com/ this is who I ordered my two new Talesuns from.

So the two new panels will be coupled with the new Blue Mountain MPPT charge controller and the damaged Helios panels will be maintained on the Trace Xantrex PWM charge controller I got from a friend as a gift. Helios has agreed to work a deal with me so I can replace the panels at a special rate, what that rate is I won't find out until either Monday or Tuesday. I did open a dialog with Helios the day everything happened. In the beginning I thought it was the charge controller but as time passed and I continued my investigation I found where I had made my error. But I also noted that Helios had failed to mark their MC4 connections with polarity. Granted someone in the business would already know many of the things I now do... but I am an amateur that lives off grid trying to save some hard earned cash and get power up.

At the end of next month I will have my system up and all my appliances running on it. The 12V system I started with will be partially dismantled and used for lighting only in the cabin. The remainder will be used to generate power in another location for lights and laptop / printer operations for my wifes business. It's funny how easy life is in the United States and you don't realize it until you move away from it and live outside the box. It's hard and it's frustrating and it's initially expensive. But in the end it's worth the freedom. I will leave this with an image of the next step in my systems implementation, a step that I will start to put in place next weekend (I have the property all to myself for 4 days!!!). Oh and a side note, once I have the new panels working I will remove the 3 damaged panels (after the replacements arrive) and use the worst of the three panels as a source of cells and see if I can repair the other two panels. I have been reading up and watching YouTube videos on how to do this... I figure might as well since the warranty is void anyhow. What could I possibly do wrong?

|

| Drawing 1 of my system reconfiguration |

|

| Drawing 2 of my system reconfiguration |

Dear Mr. Brucker,

It is with extreme humility that I write to inform you that the damage to the panels is due to reverse wiring, which was done by myself. The only thing that would be "wrong" on the side of Helios, is that the MC4 connectors on the panels were not clearly marked positive / negative as the MC4 cables I used to connect the panels to the combiner box were. Essentially I used the markings on the MC4 cables that I bought separate from the panels as my guide to connecting the terminal leads to the combiner box, reversing the polarity in doing so. I also failed to take voltage readings prior to energizing the string to the charge controller, and had I done so I would have noted the reversed polarity and been able to correct it then, and only I can be held culpable for this.

I humbly apologize for any inconvenience I may have caused with this "issue". Essentially I made a rookie mistake one that I didn't make with my 12V system as the connectors on the panels were clearly marked and that let me know how to connect the wires to the combiner box. How this happened is that when I was connecting the 12V panel to my other system, I saw the + symbol on the solar panel connector and when I plugged it into the MC4 cable, it was the - cable that went into the + cable. Seeing this I realized then that what it marked - is actually + and + is actually -. I came to this realization this morning after sleeping on the issue at hand when I woke up, went out to the array and validated it with a multi-meter.

My wife has asked that I inquire about the possibility of replacing these panels at cost, and all I can do is ask. I realize and admit that I am the one that made the mistake (one I will never make again), and that the only culpability I can find on the part of Helios is the lack of polarity identification on the MC4 connectors / cables on the panels which influenced the error. In closing thank you for your time and effort on this matter.

Sincerely,

McDian

Tuesday, August 14, 2012

System of error and disaster...

So yesterday I called Missouri Wind and Solar (they are the folks I got my load divert / charge controller from) to validate my connection set-up. And it's a good thing I did as it turned out I had it wrong. The problem started with conflicting connection instructions that were provided by the company. I tried to follow one set but the referenced numbers were not in existence. So I used the other set and it lacked clear verbiage. So I enlisted a friend whom of which is smarter than I am with electrical stuff and he deduced how the system should be wired by running some tests on a key element, the load divert solenoid. Well... he deduced wrong. Nothing was damaged, but the batteries were getting no charge by the panels as the panels were essentially dead-headed.

Anyhow I got the correct way to wire the panels into the system from the manufacture so I raced home to implement the corrections. Being a "smart" person I first isolated power coming in from the panels so I could make the corrections. Once I was finished and gave the system a good eye-balling I closed the switch to allow the panels to charge the batteries when I heard three distinct loud "clicks"... yup, all three breakers for the panels tripped. Turns out I wired those in backwards. How the hell was I supposed to know how to wire them in!? There was no indication as to which side was hot in, or how current flowed on either the package or the breakers. My friend Rick is the one that pointed out I may have the breakers installed backwards. He was right, they are operational right now and have not tripped yet since I turned them around.

So I learned something else that wasn't obvious... but in the process I thought I had smoked the multi-meter I was loaned/using. I configured the multi-meter to read from the 10A leg so I could see how many Amps each panel was producing. But I forgot to move the probe back to the voltage leg and when I went to test voltage on the batteries **POOF** the smoke got out and the meter stopped working. When I went up to check on the Kill-a-Watt and circuit breakers this morning I noticed the meter was functional again. So apparently I am being given a second chance to melt that fucker!

So today when I get home I will be installing a nice grounding system for my inverter... which is now sitting next to me in my office! Yay! Then I will install the new inverter and if I have time, fix the other issue I have and that is with my Tri-Metric meter. I am just on the edge of the maximum permissible distance for the CAT5 cable I am using to connect my 24V array to the Tri-Metric system. So the solution is to double up the CAT5 which I can do as my friend Rick gave me a spool of the stuff. I hooked it last night but the readings are all funky and the only explanation I can find is that the wire is insufficient diameter to carry the signal correctly. Easy fix for the most part!

The grounding rod is an interesting pickle though... but I think I have a great solution. I have been looking about and it seems that 8ft is the standard depth for a grounding rod. But you can get away with two 4ft rods that are linked together. So I will be looking about the property for some good material to use for a grounding rod set-up. I am questioning the one that is currently in place as I didn't set it and I have no idea how deep it is let alone it's conductive qualities. From what I am reading I can pretty much use just about any conductive piece of steel or metal and I believe we have some re-bar that I can use. I will research the feasibility of using re-bar as a grounding rod before I move forward though.

I am also going to stop by West Marine and pick up some more wire for the new inverter since I will have to mount it differently than I had planned originally. The Trip-Lite 2400W 24V inverter I just got weighs 40lbs so it's nothing like that POS Chinese 3000W 24V inverter I started with. So today is going to be busy and with that I end this entry... soon I will have the main system up and running... and yes, I will post final photos of the system after it's cleaned and installation is completed.

Anyhow I got the correct way to wire the panels into the system from the manufacture so I raced home to implement the corrections. Being a "smart" person I first isolated power coming in from the panels so I could make the corrections. Once I was finished and gave the system a good eye-balling I closed the switch to allow the panels to charge the batteries when I heard three distinct loud "clicks"... yup, all three breakers for the panels tripped. Turns out I wired those in backwards. How the hell was I supposed to know how to wire them in!? There was no indication as to which side was hot in, or how current flowed on either the package or the breakers. My friend Rick is the one that pointed out I may have the breakers installed backwards. He was right, they are operational right now and have not tripped yet since I turned them around.

So I learned something else that wasn't obvious... but in the process I thought I had smoked the multi-meter I was loaned/using. I configured the multi-meter to read from the 10A leg so I could see how many Amps each panel was producing. But I forgot to move the probe back to the voltage leg and when I went to test voltage on the batteries **POOF** the smoke got out and the meter stopped working. When I went up to check on the Kill-a-Watt and circuit breakers this morning I noticed the meter was functional again. So apparently I am being given a second chance to melt that fucker!

So today when I get home I will be installing a nice grounding system for my inverter... which is now sitting next to me in my office! Yay! Then I will install the new inverter and if I have time, fix the other issue I have and that is with my Tri-Metric meter. I am just on the edge of the maximum permissible distance for the CAT5 cable I am using to connect my 24V array to the Tri-Metric system. So the solution is to double up the CAT5 which I can do as my friend Rick gave me a spool of the stuff. I hooked it last night but the readings are all funky and the only explanation I can find is that the wire is insufficient diameter to carry the signal correctly. Easy fix for the most part!

The grounding rod is an interesting pickle though... but I think I have a great solution. I have been looking about and it seems that 8ft is the standard depth for a grounding rod. But you can get away with two 4ft rods that are linked together. So I will be looking about the property for some good material to use for a grounding rod set-up. I am questioning the one that is currently in place as I didn't set it and I have no idea how deep it is let alone it's conductive qualities. From what I am reading I can pretty much use just about any conductive piece of steel or metal and I believe we have some re-bar that I can use. I will research the feasibility of using re-bar as a grounding rod before I move forward though.

I am also going to stop by West Marine and pick up some more wire for the new inverter since I will have to mount it differently than I had planned originally. The Trip-Lite 2400W 24V inverter I just got weighs 40lbs so it's nothing like that POS Chinese 3000W 24V inverter I started with. So today is going to be busy and with that I end this entry... soon I will have the main system up and running... and yes, I will post final photos of the system after it's cleaned and installation is completed.

Monday, August 13, 2012

Online... mostly!

Okay, so I finally got the 24V system up and running. It took a lot of goading to get the wife on board and help but we did it! The panel mounting system had to be built which is where I needed my wifes help (I will admit it right here... she is a better carpenter than I am, but I rock in the electrical and mechanical world!). Together we built the frame that is being used to support our panels. After the frame was built we then hefted the panels up and I went to work making and testing connections.

The image below is looking up at the solar panels right after we had their initial installations completed and I had connected them to the charge controller. As you can see we used a wood frame made from 4x4's and 2x4's. The panels (I still have to clamp them down) will be clamped to the frame using non-conductive, non-metallic clamps. The entire reason behind using a wood frame was to eliminate several potential issues. The first of which is a possible ground/short condition between the panel frames and support frame. Next is the sheer cost of either buying or building a frame out of metal, and third bi-metallic corrosion is a serious issue that can occur which raises it's own list of issues.

If you look just below the middle panel you will see the combiner box that I put together with all the guts connected. I thought we were going to place the panels up higher on the roof but the wife said no, let's try them here first. So I evaluated the area and agreed it would be perfect for both summer and winter collection. The only issue is an apple tree which we will be trimming soon. Otherwise we are getting excellent performance from the panels where they are right now. The next image is a side view, and there you can see the apple tree I referred to earlier. Also you can see the upper locking board we are using to ensure the panels don't go any where.

One thing about where we live is the wind during the winter months can rip through our property at speeds as high as 80mph in gusts. And that means if it isn't locked,tied, nailed or glued down... it will end up in the neighbors yard. Anyhow the lower frame is metal and we chose to build the connections to the ground out of metal for the strength then we used wood for the upper frame to tie it all together. This weekend I will be installing the ground / lightening arresting system for the panels so as to protect them in storms. We don't get many electrical storms in our area and if we do it's usually one flash of lightening, a big ass boom then a ton of rain.

In the next image is another view of the combiner box. I still have to seal the penetration holes I drilled for my cabling but I am waiting for another couple of weeks while I tweak the system and verify performance. A lesson I learned on my 12V system. The one thing that will happen is the combiner box will be moved to a different location and the lead wires out will be shortened which will increase my efficiency while reducing loss even more. As it is I have already over engineered the system to the point that my theoretical loss is less than 1%. I had a friend who is a retired electrical engineer come up and look at my system, look at my design drawings and specifications and the first thing he said is the way I have it designed and built is that if I see more than a 1% loss he would be surprised.

A bit more on the combiner box, I may have covered this already but I will do it again just for learning purposes. The combiner box it nothing more than an 8x8x4 plastic junction box. I bought two DIN rails and two lugs for the larger cable (4AWG). Then I went to West Marine and bought three 15A DC rated circuit breakers. You're gonna love this, the circuit breakers are held together as a group by a piece of plastic I cut out of a yogurt containers. Then each breaker is wired into the positive leg DIN rail. The solar panels are then each individually connected to a breaker. Now this allows me to isolate panels as needed for what ever reason I may have. It also provides over current protection in the event a panel surges, which I was told can possibly happen in colder weather.

The totals cost for making my own combiner box is around $50-60.00. And it provides the connection point with protection I need plus I have a more intimate knowledge of how my system is put together which allows me the ability to trouble shoot and repair my system much faster.

Okay this next image is the battery house again, with the cheapo inverter I am using for the interim. What you are looking at are 8 USA 6V 380AH batteries configured in a series (24V) parallel set-up that provides a total of 760AH or 18,240W of power potential. Normally this would entail using a 24V inverter as well, BUT since getting said inverter at a price point that I can pay has been proving quite the pain in the ass, I have temporarily set-up a 12V 1500W inverter to run our fridge. It works just fine but the problem is when you do this the two batteries selected drain faster than they charge... I found this out this morning when I was told by my wife that she heard an alarm from the battery house. I didn't hear it until I was 8' away (damn being deaf SUCKS! Or not :-) ) So this morning I had to change the connection points and set up the charger to recharge the two batteries we have been using. Word of advice... don't do it.

Now before anyone says anything, I am still working on getting things put together so no it's not the best or cleanest looking set-up. But one or two more good weekends and it will look more presentable and be cleaned up. People who know me know I can't stand this kind of mess but... it's a work in progress at the moment.

Now on the inverter issue, I finally resolved this issue this morning. Originally I had ordered this inverter here --> Tripp Lite PowerVerter® Plus 2400W Industrial-Strength Inverter with 2 Outlets from Provantage but due to a comedy of errors (I didn't think it was very fucking funny!) the inverter was back-ordered with no known date of delivery. SO I found the same inverter on Amazon for about $50.00 more but it will be here tomorrow and will be installed tomorrow evening after I get off work.

Now some more really good information I learned. When I started this project I went in with very little knowledge or experience. I didn't know how to really get things going but as I have been moving deeper into the solar / off-grid world I have learned a lot through experience. And one area I made a mistake was in sizing my inverters and my initial system designs. Oh no the system I have is more than capable of doing what I need, but I goofed on my fridge calculations. And I realized that this weekend when I fired my fridge up. In my earlier posts I said 1-1/2 to double the amp rating should be factored in for your fridge or any motor start up. Man... I was not even in the ball park!

So I have a Kenmore refrigerator it was purchase in 2006. Not very old but very efficient! When I was gathering my data for the system design I overlooked how many watts this thing consumed while running. I did the math and according to the math I should be pulling 4.9A at 588W of power... nope! So when this fridge is running it draws 1.69A at 202W and that's for about 10minutes after starting up. Once it's settled down it pulls 1.37A at 164W! For a front load fridge that's 6-8 years old! Not bad! And now that we have insulated it even more, the run times should be reduced. Now back to the area where I screwed up... the start up of this fridge is a whopping 13.8A at 1660W!!! That's to start the fridge! I was WAY off in my estimates. I was also off in my run time consumption. According to the Kill-a-Watt over a 24hr period the fridge burned 2.3kWh of power.

Now looking at the system I have in place I got the solar capacity perfect (it will carry the remainder of my load as well as the fridge) And daily I will be driving my batteries down to an estimated 25% which is perfect! And so long as we have average solar days the system will produce that and more. But the whole point of this particular diatribe is when you are dealing with compressors or high load motors, give yourself about 40-60% for start up demand, the idea is to ensure your inverter can handle a massive current surge without tripping on an over current fault. The reason I say that is an 800W inverter is more than enough to carry my fridge but the startup current exceeds the 800W inverters capacity and so it's a non starter. The 1500W inverter I have right now... it can take the fridge start up but that's it. I can't have any other loads on that inverter.

But tomorrow it won't matter as I will be installing the CORRECT inverter that is designed to handle the load AND work with the system voltage. I think that's all for now, I will make another entry once I have things cleaned up with the system and I have more actual use data. Kill-a-Watt... use them! Serious you can't manage what you can't measure folks.

Okay... here is the system drawing I have with some of the material requirements annotated.

The image below is looking up at the solar panels right after we had their initial installations completed and I had connected them to the charge controller. As you can see we used a wood frame made from 4x4's and 2x4's. The panels (I still have to clamp them down) will be clamped to the frame using non-conductive, non-metallic clamps. The entire reason behind using a wood frame was to eliminate several potential issues. The first of which is a possible ground/short condition between the panel frames and support frame. Next is the sheer cost of either buying or building a frame out of metal, and third bi-metallic corrosion is a serious issue that can occur which raises it's own list of issues.

| 3- 300W / 24V Helios 7T2 panels |

One thing about where we live is the wind during the winter months can rip through our property at speeds as high as 80mph in gusts. And that means if it isn't locked,tied, nailed or glued down... it will end up in the neighbors yard. Anyhow the lower frame is metal and we chose to build the connections to the ground out of metal for the strength then we used wood for the upper frame to tie it all together. This weekend I will be installing the ground / lightening arresting system for the panels so as to protect them in storms. We don't get many electrical storms in our area and if we do it's usually one flash of lightening, a big ass boom then a ton of rain.

| 3- 300W / 24V Helios 7T2 panels side view. |

| Home made combiner box connected and providing power |

The totals cost for making my own combiner box is around $50-60.00. And it provides the connection point with protection I need plus I have a more intimate knowledge of how my system is put together which allows me the ability to trouble shoot and repair my system much faster.

Okay this next image is the battery house again, with the cheapo inverter I am using for the interim. What you are looking at are 8 USA 6V 380AH batteries configured in a series (24V) parallel set-up that provides a total of 760AH or 18,240W of power potential. Normally this would entail using a 24V inverter as well, BUT since getting said inverter at a price point that I can pay has been proving quite the pain in the ass, I have temporarily set-up a 12V 1500W inverter to run our fridge. It works just fine but the problem is when you do this the two batteries selected drain faster than they charge... I found this out this morning when I was told by my wife that she heard an alarm from the battery house. I didn't hear it until I was 8' away (damn being deaf SUCKS! Or not :-) ) So this morning I had to change the connection points and set up the charger to recharge the two batteries we have been using. Word of advice... don't do it.

Now before anyone says anything, I am still working on getting things put together so no it's not the best or cleanest looking set-up. But one or two more good weekends and it will look more presentable and be cleaned up. People who know me know I can't stand this kind of mess but... it's a work in progress at the moment.

Now on the inverter issue, I finally resolved this issue this morning. Originally I had ordered this inverter here --> Tripp Lite PowerVerter® Plus 2400W Industrial-Strength Inverter with 2 Outlets from Provantage but due to a comedy of errors (I didn't think it was very fucking funny!) the inverter was back-ordered with no known date of delivery. SO I found the same inverter on Amazon for about $50.00 more but it will be here tomorrow and will be installed tomorrow evening after I get off work.

Now some more really good information I learned. When I started this project I went in with very little knowledge or experience. I didn't know how to really get things going but as I have been moving deeper into the solar / off-grid world I have learned a lot through experience. And one area I made a mistake was in sizing my inverters and my initial system designs. Oh no the system I have is more than capable of doing what I need, but I goofed on my fridge calculations. And I realized that this weekend when I fired my fridge up. In my earlier posts I said 1-1/2 to double the amp rating should be factored in for your fridge or any motor start up. Man... I was not even in the ball park!

So I have a Kenmore refrigerator it was purchase in 2006. Not very old but very efficient! When I was gathering my data for the system design I overlooked how many watts this thing consumed while running. I did the math and according to the math I should be pulling 4.9A at 588W of power... nope! So when this fridge is running it draws 1.69A at 202W and that's for about 10minutes after starting up. Once it's settled down it pulls 1.37A at 164W! For a front load fridge that's 6-8 years old! Not bad! And now that we have insulated it even more, the run times should be reduced. Now back to the area where I screwed up... the start up of this fridge is a whopping 13.8A at 1660W!!! That's to start the fridge! I was WAY off in my estimates. I was also off in my run time consumption. According to the Kill-a-Watt over a 24hr period the fridge burned 2.3kWh of power.

Now looking at the system I have in place I got the solar capacity perfect (it will carry the remainder of my load as well as the fridge) And daily I will be driving my batteries down to an estimated 25% which is perfect! And so long as we have average solar days the system will produce that and more. But the whole point of this particular diatribe is when you are dealing with compressors or high load motors, give yourself about 40-60% for start up demand, the idea is to ensure your inverter can handle a massive current surge without tripping on an over current fault. The reason I say that is an 800W inverter is more than enough to carry my fridge but the startup current exceeds the 800W inverters capacity and so it's a non starter. The 1500W inverter I have right now... it can take the fridge start up but that's it. I can't have any other loads on that inverter.

But tomorrow it won't matter as I will be installing the CORRECT inverter that is designed to handle the load AND work with the system voltage. I think that's all for now, I will make another entry once I have things cleaned up with the system and I have more actual use data. Kill-a-Watt... use them! Serious you can't manage what you can't measure folks.

Okay... here is the system drawing I have with some of the material requirements annotated.

Wednesday, August 1, 2012

24V System Update

We

have movement... finally! So I did exactly what I tell people not to

do and bought cheap... silly me it ended up costing me far more than

money... it's also costing me time and stress. Anyhow currently I

have the majority of my infrastructure in place. The panels will be

mounted soon, the batteries are connected and tested. All I need to

do next is top charge them while I run the fridge and freezer on

generator to drop their temps down till their compressors stop

running.

So

let me back track here a bit and cover WHAT I have on hand right now

and where it came from. Currently I have the following items:

1

– PWM charge controller from Missouri Wind and Sun with a 600W

divert load built in

1

– Dual Pro PS 12/24V 30 A 2 Bank Waterproof Charger # DP15/2

3

– Helios 7T2 300Watt Monocrystaline panels

1

– DYI combiner box

3

– 15A breakers for panels

2

– Isolation switches, one for the panels and one for the inverter

1

– PowerVerter Plus 24V DC Inverter 24VDC-120VAC 2-Outlet Frequency

Control

7

– Custom aluminum battery bus bars

8

– 6V 380AH L16 US Batteries in series parallel for a total of 760AH

capacity

What

is currently installed are the batteries, the charge controller +

divert load, the combiner box, the isolation switches and charger.

Once I get the new inverter I will install the panels on the roof of

the barn shown in the last of the images.

Now

to why I have to wait for a new inverter... simple, I went cheap and

it cost me more in the long run. I knew better but my impatience got

me. Anyhow the 3000W inverter I had purchased was DOA. Well sort of.

It would start intermittently but then just crap out, stop working. I

know I did everything right as I had a couple of folks that actually

do this stuff and that are smarter about electrical stuff than I

check it out. Bottom line, the Chinese POS has been sent back and I

have ordered a Tripp-Lite which should be here either Monday or

Tuesday of next week.

Okay time for some updated photos (well they were up to date when I took them!).

| Battery House - Needs doors still that's this weekend. |

| Charge Controller is in this box I am pointing at |

| This is the 600W divert load. I will need this when the wind turbine is installed |

| The divert load switch if it senses that the batteries are full and power is still coming in it will automatically divert the load. |

| American made! Just in case I don't have enough solar and wind. It does happen although rarely. |

| The batteries with the aluminum interconnects. |

So

there you have the beginning of the 24V system. And as I wrote

earlier as I move further along I will post updates and photos. Right

now I am estimating a completion date of 11-12 Aug 2012. I hope so

too... tired of waiting and TIRED of the propane fridge!

Tuesday, June 26, 2012

Slowly getting there...

Okay the 3 - 300W Helios 24V monocrystaline panels are in, the 8 - 6V 380AH deep cycle batteries are in, the charge controller with divert load is in, the 3000W 24V pure sine inverter (cheap Chinese brand... if it makes it 2 years I will be happy). Pretty much everything I need is in except the battery terminal connections and a welder so I can manufacture an adjustable rack system for my panels. I found out that the cables I need to run for AC power are already in place!!! Yay for small miracles! So while I have pretty much everything I need... I am once again in a holding pattern. So this is just an quick update to let you know it's coming, real soon with photos to boot!

Peace Love and Five Finger Death Punch!

Peace Love and Five Finger Death Punch!

Friday, March 23, 2012

24VDC system in the making!

Hello!

So it seems that I will in fact be able to move forward with my 24VDC

system in the very near future after all! Of course as things would

be I have to make some changes to how I will proceed but the fact

is... I will very soon be building my new system!!! And yes, I will

post with images the new system as it goes up and comes on line.

This

particular post I will be focusing on a new spreadsheet I have set up

that I would love to share with you that are reading. The idea was to

create a way to track costs and really compare components by cost,

feature and need. The spreadsheet (which I will link to at the bottom

of this post) is essentially a live one that I am using to build my

upcoming 24VDC system. I have a limited budget (yeah... really who

doesn't today!) so I need to put a lot of thought into the items I

purchase and where my money goes.

In

an earlier blog post I mentioned converting my AC refrigerator and

freezer to DC, and this is still going to happen, just not for a

while. The conversion cost is pretty high and while the payback is

reasonable I just don't have the money at the moment to do it. So I

will be using an inverter to run the refrigerator for now. Now

currently I expect the refrigerator to consume about 90AMPS of power

per day. BUT I have a plan to reduce that!

See

the idea is to improve the efficiency with as little cost / effort as

possible. And the only real way I can do this is to improve the

insulation of the current equipment. And since I will have to do this

anyhow for the DC conversion, well I will be just one step ahead! So

the wife and I will add hard foam insulation to the exterior of the

fridge (See

here) then she will put a nice finish exterior over that. I will

admit right here and now my wife is better than I am with finish

carpentry so I do the rough stuff and she does the finish. By adding

the extra insulation and installing it in such a way that is seals

around the gasket area, we will increase the efficiency of the chill

box and reduce the run times of the compressor. This should net us an

estimated 30-40% decrease in power consumption.

And

if it works as I think it will (it's all theory right now) then I can

do the same thing for my deep freezer that I have. And that would be

the bomb diggity right there! So that is really the major change I

have in my current plans.

Now

the planning spreadsheet that I have put together is pretty simple to

use really. And all you have to do is download it and tweak it for

your needs. I was going to use Google docs again but it's a pain in

the ass to take the spreadsheet and recreate it there so I am using a

free file sharing site for now. Anyhow to use it is simple, the areas

that are light gray and have a border around it are where you make

your manual entries. The top portion is called the component pricing

list. Here you enter the component(s), their unit cost (how much each

item costs) the tax rate if applicable and the shipping rate. Keep in

mind this is not accurate and is essentially and estimation form. The

whole idea is to allow you to see how much your components will cost

and plan accordingly.

It

also again will touch on your load requirements and will you meet

them with the items you are selecting. Anyhow the next area in the

components list is the source and URL, where are you planning on

getting this stuff. As you enter items the F, G and H fields will

auto-calculate for you. Then in column|row H12 a total sum will be

auto-calculated. In column|row H13 you enter the amount you have

budgeted and below that the estimated remainder will be

auto-calculated for you.

Now

you will notice that in column|row I14 there is an area that is gray

and had borders, this is where you put the actual remaining amount.

What I mean by that is I will often times start the purchase process

so I can see exactly how much shipping and tax will be and get a

total value. I will then take that total and put it somewhere and add

other actual totals to it. I don't commit the purchase (not until

I am finished shopping and I have the $$ in place!) I simply

close the web page and move to the next item. This is one way to

validate my buying estimations. It's also a way for me to test the

web site if I have never purchased from them before, see if there is

anything that strikes me as odd. Also as an added method of

protection I use a pre-purchased Visa with only $5.00 on it, that way

if it turns out to be a funky site I lose $5.00 and nothing else. By

doing this I can also use a bogus address during the test phase,

again as a way to protect myself and test the site.

Anyhow

the next section is the battery breakdown. By this time you should

have already narrowed you battery choices down to a brand, voltage

and AH rating as well as the configuration you need. This section is

for you to validate your load / run times as well as ensure that when

you start selecting solar panels (and wind turbines as well, hell

even pelton wheels!) you are selecting enough to replenish your

batteries. So you enter the following information, manufacture and

model, voltage, AH Rate, quantity, how many in series (this will give

you your system voltage) and how many sets in parallel to get total

system AH. Once this is done you move to the next section which is

the load!

In

the load section you enter the nomenclature of the item that is the

load, the voltage the amps and how long you think it will run. All of

this information should be readily available from earlier research

you should have done by now. Anyhow this will give you your total

watts, kW and amps requirements. In column|row G26 your total daily

power demand will be auto-calculated, below that you need to enter

what you estimate to be system loss due to inefficiency as well as

line loss. 10% is generally a pretty good number to start with. This

will auto-calculate your total load below and this is what you need

to make up every day with your solar, wind or pelton wheel. Now keep

in mind as I said in earlier posts everything you have is theoretical

you may see better performance or worse performance of your system

and that all depends on weather, temperature, quality of equipment,

quality of connections and installation and just luck of the draw.

All the numbers I have listed assume realistic worse case scenarios

and chances are pretty damn good I will see much better performance

than I show on paper.

When

I ran the numbers for the existing system I have now, they showed far

worse performance that I am seeing. Although the exception to that is

on really cold and cloudy days the system is performing almost

exactly as my worst case scenarios predicted. So I suppose in the end

it's a wash. Now the one thing I didn't do was account for the wind

turbine in my scenario that you will see in the planning spreadsheet.

That is because the wind turbine will not come into significant play

until the winter. Sure right now it will produce power but that is

diminishing as we move into spring. Fall and winter is where I will

see the real production capacity of my wind turbine.

Alrighty

I have rambled enough, the next area is the panel capacity cost

analyzer. This is where you search the web for solar panels that meet

YOUR requirements. I need panels that will charge a 24VDC system so

therefore all my panels that I have selected are rated 24V+. you

really need to get accurate data here... otherwise you could very

well under power you system. Generating more than you need is not a

problem, with a load diverter you don't have to worry. Remember

during the summer you will produce far more than you will consume, if

you designed your system correctly. And during the winter you should

hit on the nose or slightly over with your production to use ratio.

Some will argue this is a poor way to design systems... but then

again those people are also grid tied. I am not so therefore I have

to follow a completely different paradigm than grid tied folks. And

if you are looking to be off grid you will have to follow the same

paradigm I am.

So

with the cost capacity analyzer you will need to enter the panel

manufacture name and model (well you don't have to... but that'll

sure fuck things up for you later!) then what type of panel is it.

Remember monocrystaline is the best! But it's also generally the most

expensive! Next enter the individual panel wattage, volts and amps

(the amps are the most important aspect as they determine actual

charge capacity!) next you enter the panel quantity and the unit cost

(individual cost or if sold as such the pallet cost). Now once you

have done that the sheet will auto-calculate sub-total, tax,

shipping, total cost, total amps and total watts. In the time slot

enter the estimated full sunlight of the shortest solar day of the

year. Again you are planning for the worst return on power. Once you

do that then total amp will auto-calculate which tells you how many

amps you will generate. This is important as you need to replace the

amps you consumed. So the spreadsheet will then auto-calculate the

power balance, in other words it will take your estimation of daily

power consumption and subtract your estimation of power production.

The closer to zero you can get the better. If you go negative then

schweet! The next field you will enter data into os the source / URL

from whence the panels may come.

Now

continuing across the sheet you will see a cost per amp and cost per

watt calculation. The lower the cost per watt the better, but you

knew this already! So what I do is I sort by the actual cost

difference then I look at the power balance and the cost per watt.

Sometimes you will pay more overall but it washes out in the cost per

watt AND you are close to or below zero on your recharge capacity.

And

there ya have it! Play with it and see what you come up with and if

you find an error or have a question as always ask and let me know so

I can correct it.

Link

to the planning spreadsheet:

http://www.4shared.com/office/DKs7vhoI/file.html

Peace,

Love and Five Finger Death Punch!!!

Wednesday, March 14, 2012

New system on the horizon...

Okay,

so I am coming into a bit of money I didn't expect. Which is great!

Sadly though as is the story of my life... it enough to get a good

start but not enough to get it done. Which means I will have to do

things in piece meal again.

But

that's not the reason for this post! No siree Bob! This post is to

talk about a new system I will be building for the cabin and

eventually moving to the main house. If you have read my other posts

you already know what I have in place right now. But this new system

will be a 24VDC system (increase efficiency of the system overall)

with a custom fridge and DC water heating.

I

have been shopping around for a DC refrigerator for some time now and

while I have found some great fridges out there... I can't afford

them! So in my searches I found this link:

And

since I have an AC fridge already as well as the majority of the

materials I need to build with... why not? The great thing is I have

an HVAC technician that is going to help me with sizing the